Why you should replace brake rotors – NOT resurface them.

It has become common for a typical brake repair to include replacement of pads and rotors within the last several years.

Many car drivers are used to brake rotors lasting through 2-3 sets of brake pads – but newer vehicles, and smarter repair shops – are now replacing rotors instead of machining them.

Commonly; customers will chalk this up to “The repair shop/parts store is just trying to make more money.” However, that’s not the case.

Even in times of parts shortages, it’s not usually extremely expensive to replace rotors – compared to the cost of properly machining them. There aren’t significant profit margins included in brake rotors and pads at most parts stores or repair shops. It’s not even something that many big repair chains ‘spiff’ (give bonuses for). So why are more and more dealerships, repair facilities, and parts vendors having their customers replace rotors?

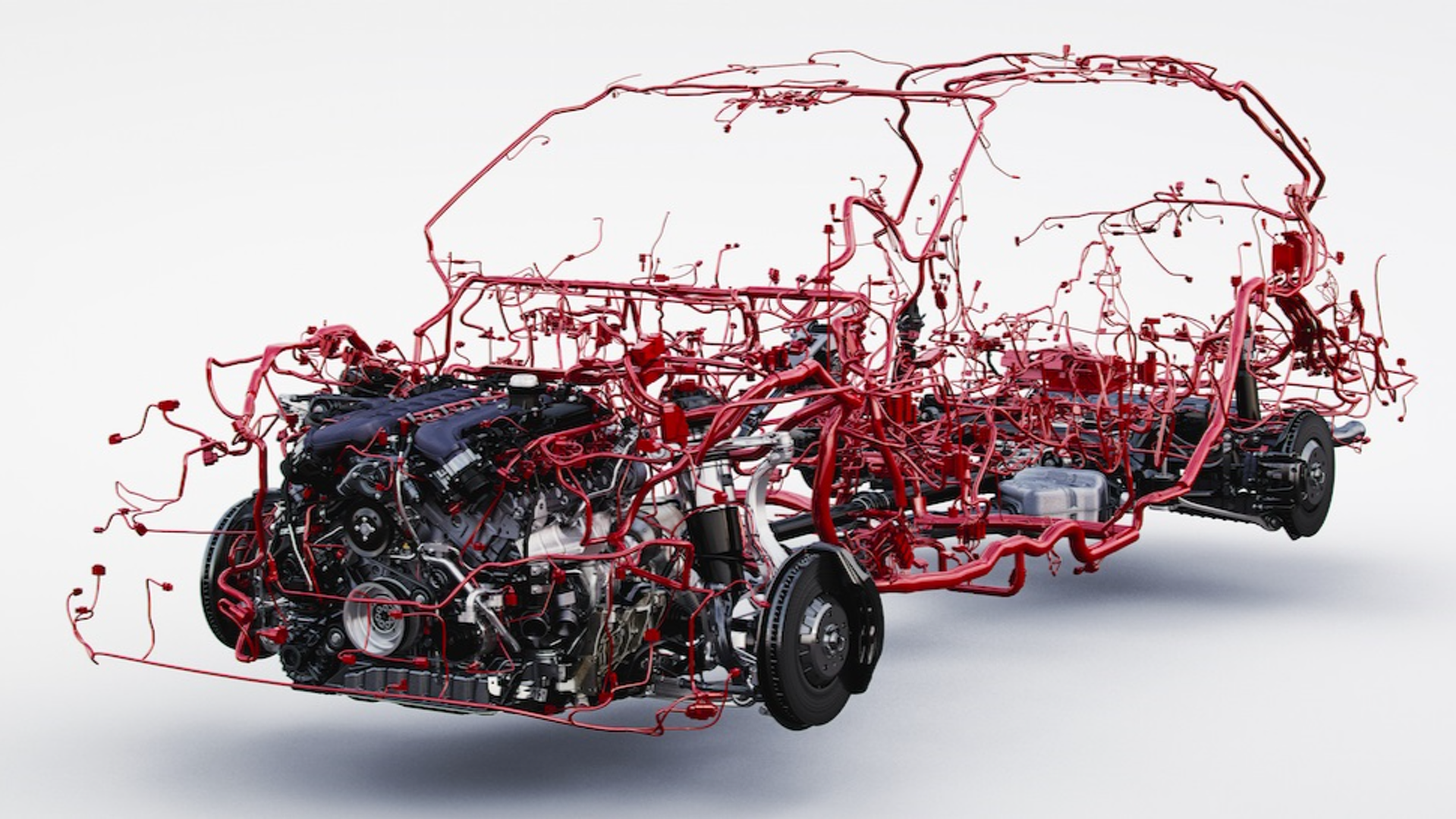

The answer comes from the development of new technologies and new vehicles. Modern cars are lighter, using less materials, lighter materials, and less robust designs. They are built to conserve fuel, maximize horsepower production and minimize weight.

“Power to weight ratio is better? Well it will accelerate faster, and stop faster! That’s great! We can shave pounds off those brakes baby!” – Some Engineer Probably

As a result – brake components, suspension components and steering components are lighter weight. Rotors today are thinner, and made of lighter alloys than their counterparts from 7-10 years ago. That means you can’t machine them as much, and it means they’re more likely to be worn down before you change the brake pads. It also means that slight machining issues can cause drastic noises and vibrations.

Lately – vehicles are being released with tight specifications on brake rotor ‘runout.’ This is a measurement of how ‘true’ or how flat – the surface of the rotor is. If it’s not true, the brake rotor ‘wobbles’ as it spins – like a warped record. Newer vehicles have runout limits of .002 to .003 inches! For comparison a human hair is usually around .001 inches. When you’re talking about spinning something at thousands of rotations per minute and then pressing a brake pad against it – those hairs-breadths make a difference!

The other issue that people don’t think about is heat. Your brakes function by creating friction – that’s how you stop. That process creates heat. But how do you get rid of the heat. Older brake rotors had a lot of extra metal fins and vanes inside them, they had extra material that was there simply to bleed off heat. With some vehicles having thinner, solid rotors, (meaning no vents, vanes, or extra thickness) heat dissipation becomes a problem. If you machine a rotor and take off .020 inches (whew! that’s a alot – 10x the amount of runout – but that’s normal for a brake job from a decade ago) – you have that much less metal to absorb heat, and dissipate it. Newer rotors just can’t handle being machined, or they get too hot.

When rotors get too hot, what happens? You guessed it – they warp. So you get into this vicious cycle – rotor shakes -> machine it -> Doesn’t shake but overheats – > Gets warped and shakes worse -> Re-machine it – > And so on….

The final nail in the coffin is your brake pads. New brake pads have a nice, machined, flat and true surface. When you try to smash that against the warped, grooved, uneven surface of your old rotors – it just doesn’t work right. You don’t get enough surface contact and friction to stop the car correctly; you have spaces and gaps that allow the pad to move and vibrate and squeak; and you’re now creating extra wear on brand new pads, trying to get them to wear down and match the uneven surface of the rotor. Common sense just says this whole thing is a bad idea.

We can’t stress it enough. If you want your brakes done correctly, and you don’t want to have to keep coming back for repeat brake problems – have your pads AND your rotors replaced at the same time.